3D-Printed Soft Mesh Robots

Scientists have developed a 3D-printed flexible mesh robots that can be controlled via magnetics while floating on water. "This research shows capabilities in the emerging field of combining 3D printing and soft robotics," says Orlin Velev, S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering at North Carolina State University.

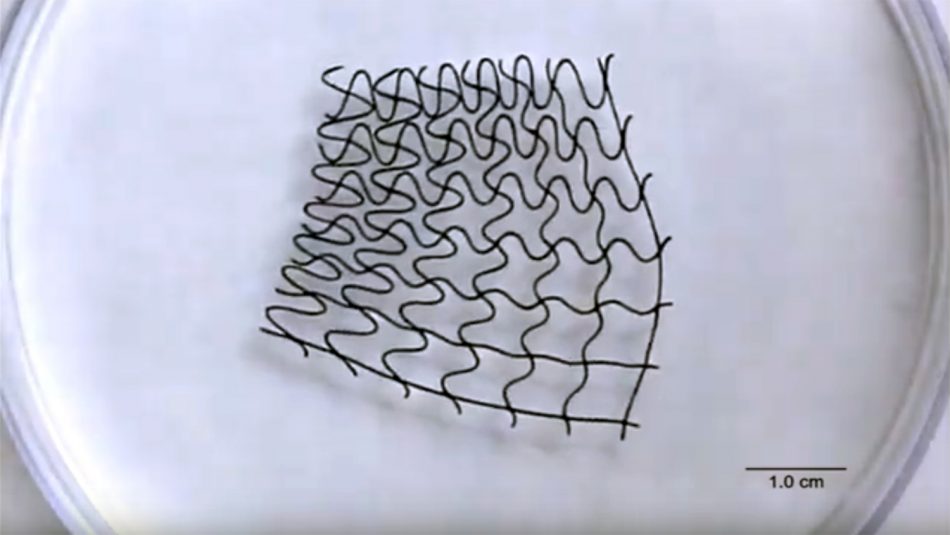

The structures were developed from "homocomposite thixotropic paste" derived from silicone microbeads and bound by liquid silicone that is enclosed in water. "This self-reinforced paste allows us to create structures that are ultra-soft and flexible," says Ph.D student and first author, Sangchul Roh.

The “paste” can be easily squeezed out like toothpaste but instead maintains its shape without dripping. The researchers then used a 3D printer to shape into mesh-like patterns before being shaped into flexible silicone structures that can be stretched and collapsed by the application of magnetic fields. The have properties that can allow them to be used while floating on water.

"Embedding of iron carbonyl particles, which are widely available and have a high magnetization, allows us to impart a strong response to magnetic field gradients," says Joseph Tracy, professor of materials science and engineering and a senior co-investigator.

Results of the study were published in a special issue of Advanced Materials Technologies, where researchers indicated that the reconfigurable a structures is capable of “grabbing” a tiny ball of aluminum foil and "carrying" a single water droplet before releasing it through the mesh. "The structures are also auxetic, which means that they can expand and contract in all directions," Velev said. "With 3D printing, we can control the shape before and after the application of the magnetic field. For now, this is an early stage proof-of-concept for a soft robotic actuator.”

Source: North Carolina State University

![Master Lab Weighing: Accuracy, Compliance & Audits [eBook]](https://d3bkbkx82g74b8.cloudfront.net/eyJidWNrZXQiOiJsYWJyb290cy1pbWFnZXMiLCJrZXkiOiJjb250ZW50X2FydGljbGVfcHJvZmlsZV9pbWFnZV85MWRmZmRjMDIwNDBlMWJjMzYwN2ZiYWY2ZjI4ZGMzYzBmZGMwZGMyXzkxOTcucG5nIiwiZWRpdHMiOnsidG9Gb3JtYXQiOiJqcGciLCJyZXNpemUiOnsid2lkdGgiOjcwMCwiaGVpZ2h0IjozNTAsImZpdCI6ImNvdmVyIiwicG9zaXRpb24iOiJjZW50ZXIiLCJiYWNrZ3JvdW5kIjoiI2ZmZiJ9LCJmbGF0dGVuIjp7ImJhY2tncm91bmQiOiIjZmZmIn19fQ==)