Novel Approach For Self-Assembling Micromachines

Scientists at the Max Planck Institute for Intelligent Systems in Stuttgart have designed a novel approach for the development of micromachines. Such approach allows self-assembly of the components of microvehicles, microrotors and micropumps in an electric field. Additionally, the novel approach can prove new use in constructing medical microrobots in the human body or to design laboratory devices on a microchip.

As the microparticles that serve as the vehicle's wheels are magnetic, the vehicle can be propelled by a rotating magnetic field.© MPI for Intelligent Systems / Nature Materials 2019

For example, improving the current use of microvehicles could advance the delivery of drugs to the source of the disease as well as helping with diagnoses and taking on minimally invasive surgery. Other micromachines, which have long been an interest for medical, biological and chemical laboratories, can function as a laboratory on a microchip and save time and money on medical or environmental chemistry analyses need a room full of equipment.

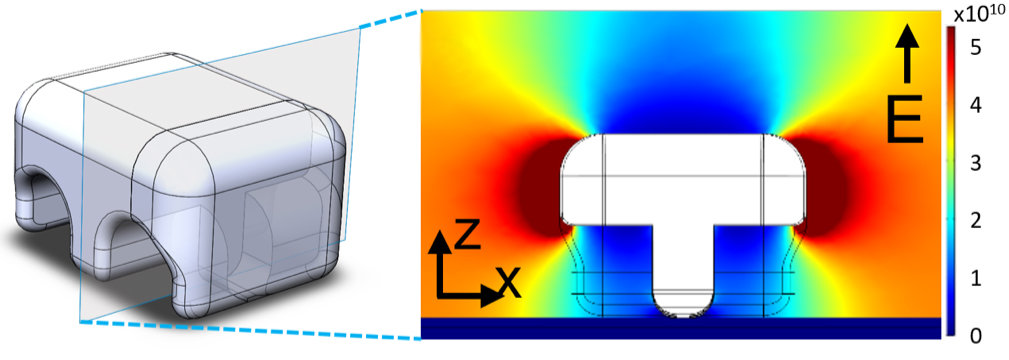

Micromachines have long relied on magnetic particles that come together in a magnetic field. Now, the novel approach—known as "dielectrophoresis”—advances self-assembly of micro-machines by utilizing an electric field of varying strengths that is “polarizing an electrically insulating plastic frame along with further plastic or quartz glass components”.

Watch this video below to learn more:

"If we change the shape of the components, we can control how the components attract each other," says Yunus Alapan, who was involved heavily in the instrumentation of the new technique.

Furthermore, researchers used the technique for the self-assembly of a magnetically propelled microvehicle with a non-magnetic chassis and magnetic beads as wheels. "We designed the chassis with wheel pockets because, structurally, this generates forces that are ideal for attracting the magnetic wheels," says Alapan. "Only seconds after we turned on the electric field, the wheels were pulled into the wheel bags."

Wheel mounting in seconds: as soon as a non-uniform electric field is switched on, the chassis of a microvehicle pulls its own wheels into wheel pockets. After just over a second, all the wheels are in place. © MPI for Intelligent Systems / Nature Materials 2019

"The components of our micromachines are not tightly bound," says Berk Yigit, who was involved in the research for his doctorate. "Rather than forming rigid connections, each part can move independently." The researchers were, therefore, able to drive the microvehicle using a rotating magnetic field that, likewise, rotated the wheels.

For a microvehicle to be able to mount its own wheels, its chassis must be designed so that a non-uniform field will cause them to be pulled towards the wheel bags. A computer can calculate how the component influences the electric field.© MPI for Intelligent Systems / Nature Materials 2019

"Micromachines that have a high degree of mobility could in the future be used to deliver drugs to manipulate individual cells -- currently, constructing machines of this size is a huge challenge," says Metin Sitti. "Our new approach has the potential to reduce the complexity of such construction."

Source: Science Daily, Nature Materials